MagnaPro packaged pumping stations

Winner of the Construction News Specialist Award for Innovation of the Year 2020, our MagnaPro is a range of fully automatic packaged pumping stations. They are suitable for pumping ground, surface, storm and foul water to a higher level when gravity drainage is not possible or economical to install.

Re-engineered from the ground up, the MagnaPro incorporates a wide range of unique features and benefits, whilst complying with all current design standards.

With a wealth of chamber size, pump, pipework, controls and other options, MagnaPro can be tailored for your specific site requirements. A wide range of options are available for you to simplify your product selection.

We’ve introduced several innovations that focus on four key areas. A common problem with package pumping stations is warping caused by poor installation or ground water pressure. So, redesigned reinforcement includes reducing flat sections to tolerate increased pressures.

Meanwhile, risks during refurbishment are reduced through captive nuts, meaning operatives need never pierce the tank wall. Aside from this, to improve outlet connection, we’ve developed a stainless-steel tank connector system offering a corrosion-free lifecycle.

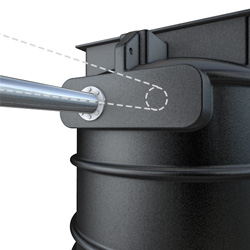

Maintenance entails the need to regularly isolate pumps from the rising main using a gate/sluice valve. Valves are typically located in difficult places, close to the chamber wall or tucked away from the access opening and so confined space entry is required, adding expense and risk to a simple task. The new pumps come with a valve access section allowing them to be manipulated from ground level, negating the risk when engineers enter tanks to isolate pumps.

MagnaPro has been shortlisted for the Water Industry Awards 20221 in the Wastewater Innovation Project of the Year.

Versatility and performance combined

INSTALLATION

CHAMBER RANGE

PUMPS

CONTROLS

|

ACCESSORIESWe offer a wide range of accessories ensuring that your pumping station meets site requirements, including:

AVAILABILITY

CUSTOMERSDomestic users, house builders, contractors, ground workers, retail outlets, schools and colleges/universities, local authorities, hotels and restaurants, etc CONSENTPrior to installation, there is a legal requirement to obtain permission from the appropriate agencies, including connection to a public sewer |

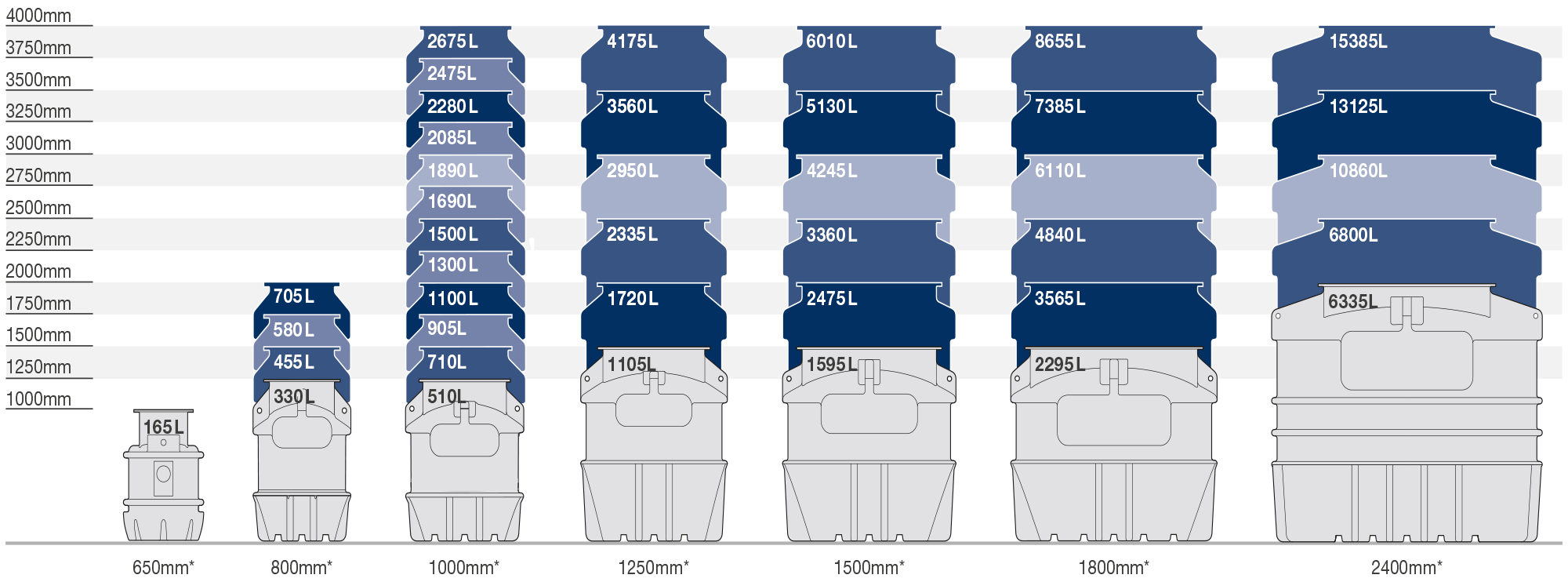

Chamber size and storage capacity

NOTE: Maximum capacities in litres (L) are from below highest inlet.

Key benefits and features

|

Tank grade polyethylene. Single piece construction. Strengthening ribs located throughout the body of the chamber providing reinforcement and anchoring. |

|

There are a variety of clear opening sizes for pump and man riding access (subject to chamber diameter) |

|

Isolation valve is accessible at cover level via the valve extension kit, preventing the need to access the chamber for valve isolation (to be specified at time of order) |

|

Lifting eyes are incorporated within the top of the chambers for assisting with off-loading and positioning |

|

Easy to install cable duct, vent duct, inlets and outlets. Single or dual outlets can be positioned to your requirements (subject to chamber diameter) |

|

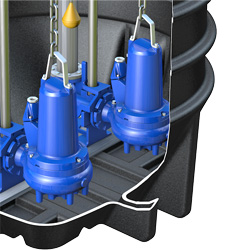

Accommodates benching in accordance with current design standards. Directs waste water towards the pump/s preventing dead zones. No flatter than 60° |

|

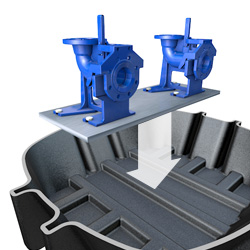

The pedestal/s is assembled onto a base plate before being sited into the bottom of the chamber. Unique chamber base construction provides strength and versatility. Integral feet providing stability |

|

Download our MagnaPro brochure for more details |

Please contact Edincare Sales on 01442 211554 from 08.30 to 17.30, Monday to Friday or via email sales@edincare.com for further information.