Client

Civil engineering and groundworks contractor

Sector

Public sector

Project Type

Installation, commissioning

Products Used

MagnaPro, Magna IP, MagnaGrand Lateral

Onsite Duration

15 days

Location

London

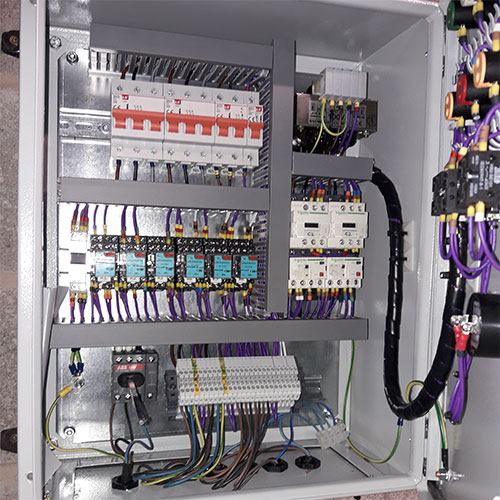

IntroductionWe installed four pumping stations at a new leisure centre and inner-city academy school that form part of the Shoreditch Park Project, a major regeneration project in the London Borough of Hackney. Our client was a civil engineering and groundwork specialist working under the main contractor Morgan Sindall. MethodAt the design phase we liaised with the project’s design practice, to ensure that the correct pump equipment and chambers / sumps were specified. We also specified the electrical requirements for the pumping chambers, including the distribution boards and the size of breakers. As is common with projects of this scale, installation was staggered to fit the overall construction programme. The leisure centre’s foul water MagnaPro pumping station was installed first. Situated in the basement, it featured two powerful vortex pumps and galvanised steel internal pipework within our award-winning reinforced polyethylene chamber (1500mmØ x 3000mmH). The next to be installed was the academy’s primary foul water pumping station (MagnaPro IP), which was situated in the basement. The sump measured 7000mmL x 2500mmW x 3400mmH and was constructed to our specification by the projects groundworking contractor. We specified a 3-degree slope from inlet end of the sump to the discharge end and 60-degree benching on the floor/wall junction. This will help ensure the waste water flows naturally towards the discharge pumps and not accumulate in dead zones. Because of the length of the sump, a grinding mixer pump with a funnelled discharge was installed at the inlet end. This pumped the waste towards the discharge pumps and ensured any solids remained in suspension. Without these measures, solid waste would settle below the inlet and become compacted over time, requiring frequent tankering. We also asked that care be taken to ensure the HDPE discharge pipework, which was set into the wall of the sump, was perpendicular and at the correct height. This ensured the internal galvanised steel discharge pipework would connect easily and securely. Our expert engineers installed the pumps sets and pipework using confined entry methods and safety equipment. The third pumping station to be installed was the academy’s secondary foul water pumping station located in the grounds. It was a 2,700mmØ x 5,000mmL Magna Grand Lateral with a GRP chamber. Lastly, a storm water MagnaPro IP pumping station was installed in the concrete sump in the grounds of the academy. After installation and commissioning of each pumping station, we tested their electrical load and issued an NIC EIC certificate to confirm that they performed to within the expected parameters. The project took place during the COVID pandemic, which required extra safety measures including lateral flow testing every time an engineer visited site. ResultsAll four pumping stations were installed and commissioned to the contractor’s programme. Operating and Maintenance manuals were created for handover to the end client, the London Borough of Hackney.

Foul water MagnaPro pumping station at the leisure centre

Storm water MagnaPro IP pumping station at the academy

Control panels

Control panel

|

|