Client

Third party service provider

Sector

Residential

Project Type

Refurbishment

Products Used

MagnaPro, tankering

Onsite Duration

2 days

Location

West London

VISIT 1We were asked by our customer, a third-party service provider, to service a twin pump foul station at a 6-unit block of flats in West London. The chamber had been emitting a foul odour. It was our first visit to the site. The pumping station is in the car park. The control panel located in a cupboard under the main staircase. On arrival there was some build-up of waste and the chamber was very dirty. The pumps were free-standing and connected to the discharge pipework by 2” flexi-hose. It is a three-float system – the top float provides both duty-assist and high-level alarm functions. Because the condition of the chamber could not be inspected, a minimal service was conducted to prevent potential harm. It was obvious that a complete refurbishment was required. The system was specified and a quotation was submitted. VISIT 2Two weeks later we attended an emergency callout. The pumping station was again emitting a foul odour. The station was at high level and neither pump was running. The fault lay in the control panel’s timer which only allows pump activation within a set time window to prevent noise disturbance for residents. The fault prevented the pumps from running at all. The timer was bypassed as a temporary measure. The owner was told that remedial work would be required to prevent an inevitable failure. VISIT 3Five weeks later we were called to the site again with a report of a foul odour. The drains had backed up and the pumps had not activated. The engineer discovered the control panel had tripped the breaker on the distribution board. It had been caused by both pumps activating at the same time and drawing too much current. The cause could be either a float problem, causing both pumps to activate on the duty-assist float or an incorrectly specified breaker. As a temporary measure, the duty assist pump was removed. We strongly recommended the owner approve the pumping station refurbishment as soon as possible. They agreed and we scheduled a return to the site to complete the work. VISIT 4The pumps, control panel and floats were all replaced, along with lifting chains and shackles. Additionally, the 2” flexi-hose was replaced with 2” Class E high pressure PVC. Edincare Drains attended the site with a combi-tanker to assist the pump engineers during the refurbishment. They emptied and cleaned the chamber then managed the inflow of waste which remained live throughout the works. This allowed confined entry by the pump engineers. Once the equipment was installed, they filled the chamber with clean water so the station could be tested. RESOLUTIONThe site now has a good-as-new pumping station which will operate reliably for many years provided it is regularly serviced.

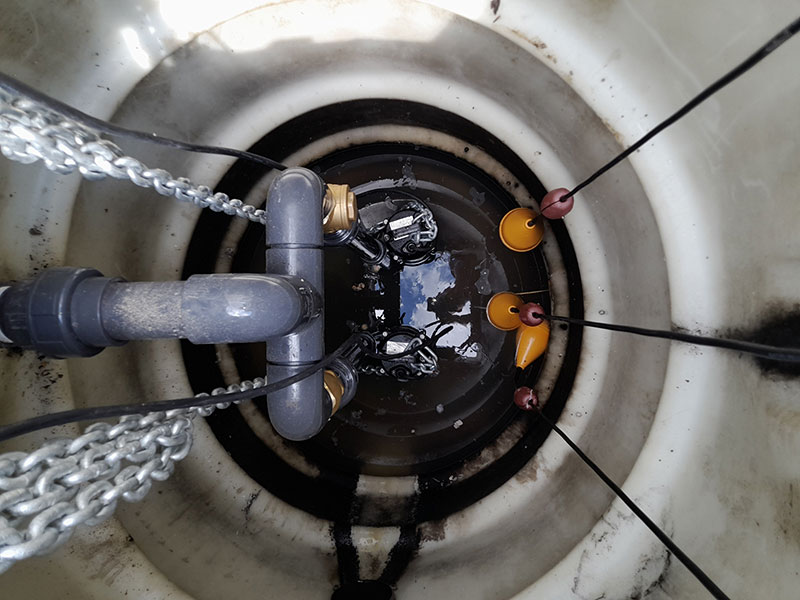

Visit 1: The pumping station on arrival.

Visit 1: The pumping station was very dirty.

Visit 1: The existing control panel.

Visit 2: Control panel timer fault

Visit 3: The foul drainage network was backed up.

Visit 3: The pumping station after visit.

Visit 4: The refurbished pumping station.

Visit 4: The new control panel.

|

|