Client

Specialist Swimming Pool Contractor

Sector

Hospitality & retail

Project Type

Installation, commissioning

Products Used

MagnaGrand IP

Onsite Duration

2 days

Location

West Wales

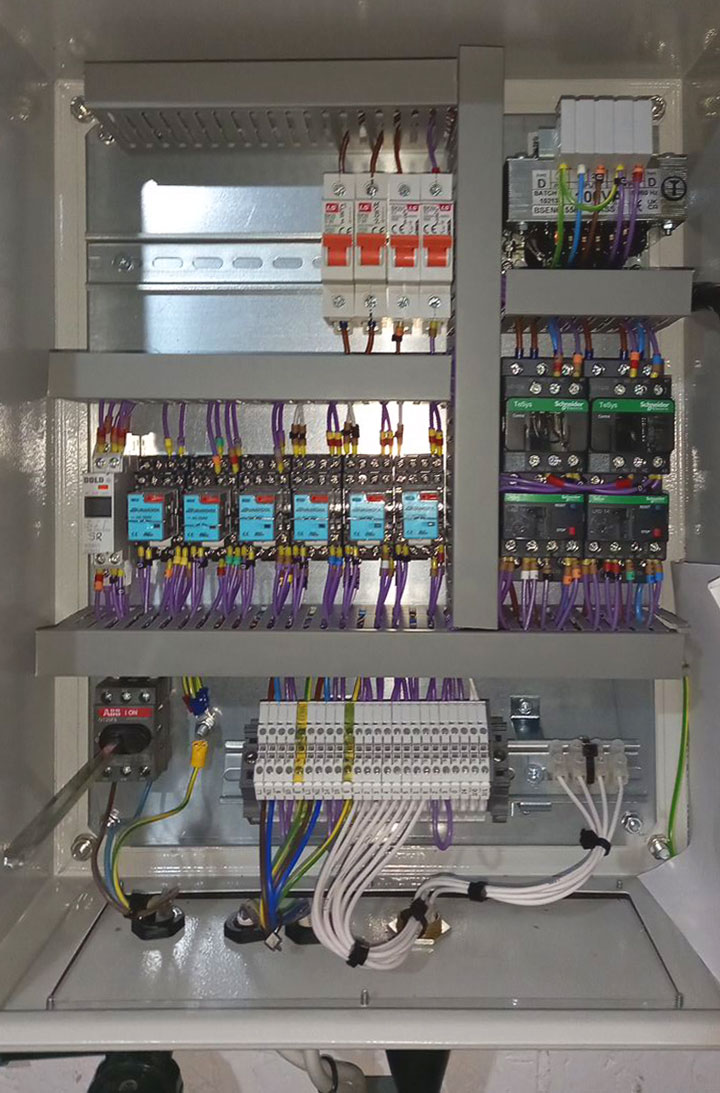

INTRODUCTIONOur client, a specialist swimming pool contractor, asked us to install a backwash grey water pumping station for a new-build commercial swimming pool at a holiday park on the Ceredigion coast near Aberystwyth. The chamber receives wastewater generated by the pool’s filtration system during the backwashing process. Under normal operation the pool’s water is filtered through fine sand which catches the small dirt particles such as dead skin cells, lotion and sunscreen particles which have not already been removed by coarser filters. Periodically this filter is cleaned by backwashing. Water is passed through the filter in the opposite direction to flush out the waste. This is diverted to an adjacent pumping station for removal to the foul drainage network. METHODThe lateral GRP chamber was specified and installed by the client. We specified the pumps and fittings considering the required flow rate and total head. Backwashing generates a large volume of waste in a short period of time, with the total volume dependent on the size of the pool. The pumps should have a sufficient flow rate to match the inflow. The chamber should have sufficient capacity to accept the total volume of the backwashed water generated in case of pump failure. Installation and commissioning took place over two days. On the first day our engineers installed all of the internal components of pumping station from fibre grid, pedestals and pumps to guide rails, unistrut, braced pipe manifold, level controls etc On the second day, they terminated the pump and float cables to gelled junction boxes and tidied all the cabling in the chamber. The control panel was installed in the pool’s plant room. Cables were routed via cable tray and terminated in the panel. Overloads were set and the control panel connected to the isolator provided. Once installation was completed, the pumping station was commissioned. Float sequences were tested. The pumps were confirmed to be stepping over and discharging correctly. Wet-testing proved the pipework and fittings were leak-free. RESOLUTIONThe pumping station is specified to fulfil its role well. Provided it is serviced regularly it should provide many years of trouble-free service. The holiday park’s visitors will be able to enjoy a swim in a clean pool, in part due to this pumping station’s unsung duty. Our engineers’ pride in their work is evident in the quality of the workmanship on display below.

The installed pump set.

Cable management.

Cable management in the plant room.

The control panel.

|

|